10 Tips for Choosing the Best Flexible Pouches Packaging Solutions

Choosing the right flexible pouches packaging is crucial for your product's success. Many factors come into play when selecting packaging. It affects presentation, protection, and user experience. The market offers various options, causing confusion for brands.

Quality materials matter. They ensure that your product stays fresh and retains its quality. Can your chosen flexible pouches withstand pressure during transport? Consider this aspect carefully. The design also speaks volumes about your brand. A well-designed pouch can attract consumers' attention instantly.

Think about functionality. Will your packaging be easy to open? What about resealability? Sometimes, overlooked details lead to missed opportunities. Make your choices wisely. Reflect on past decisions. They can guide you toward better outcomes. Flexible pouches packaging is not just an option; it’s essential to your product’s appeal and longevity.

Understanding Flexible Pouches: Types and Materials Overview

Flexible pouches have gained popularity in various industries. Understanding the types and materials used is crucial for successful packaging. These pouches often come in different shapes and sizes. Common materials include plastic, foil, and biodegradable options. Each type serves a specific purpose and caters to various products.

Plastic pouches are lightweight and versatile. They can be made from materials like polyethylene or polypropylene. These options provide excellent barrier properties against moisture and light. Foil pouches, on the other hand, offer superior protection for sensitive products. They preserve flavor and freshness effectively, but they may not be recyclable. Biodegradable pouches are emerging as eco-friendly alternatives. However, they may not always provide the same durability as plastic or foil. This creates a challenge.

Selecting the right material helps balance functionality and sustainability. Consider the product’s needs, shelf life, and storage conditions. Each option has strengths and weaknesses. Addressing these factors can lead to better packaging choices. Yet, many brands overlook the long-term impacts of their decisions. It's important to reflect on the implications of choosing flexible pouches.

Flexible Pouches Packaging Solutions Analysis

Identifying Specific Packaging Needs for Your Product

When selecting flexible pouches, it’s crucial to identify your product's specific packaging needs. Consider the dimensions and weight of your items. A pouch that is too large can result in wasted material. Conversely, a pouch that is too small may not adequately protect your product. Think about how your pouches will be used. Will they be for retail display or for direct shipping? This matters significantly.

Think about the contents as well. If your product is liquid, choose a pouch that can reliably prevent leaks. Products requiring an extended shelf life may need barrier protection against moisture and oxygen. Reflect on labeling options too. Eye-catching designs are essential for attracting buyers, but they also must communicate vital information.

Remember, trial and error is part of the process. You may find that your initial choice leads to unforeseen issues. Pack a few samples and conduct a test run. Gather feedback from your team or customers. Evaluating flaws and successes helps improve future packaging decisions, making this step invaluable.

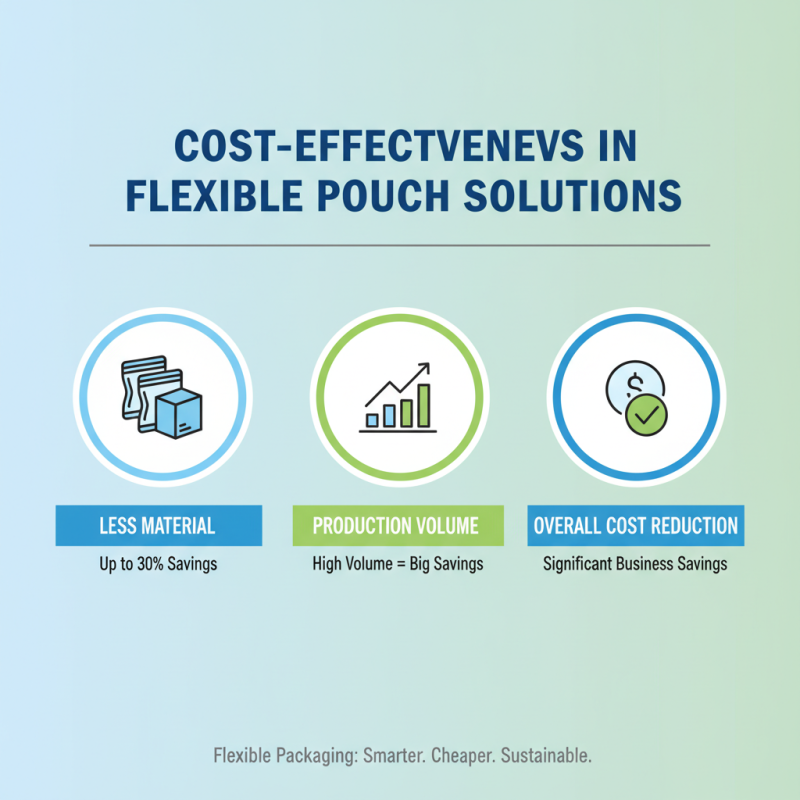

Evaluating Cost-Effectiveness of Flexible Pouch Solutions

When evaluating cost-effectiveness in flexible pouch solutions, several key factors come into play. Materials used in pouches can greatly affect costs. For instance, flexible pouches often require less material than rigid containers. Reports indicate that businesses can save up to 30% on packaging materials alone by opting for flexible options. This is significant when production volumes are high.

Labor costs are another critical aspect. Flexible pouch packaging typically requires less time for filling and sealing. A study revealed that companies reduce labor costs by approximately 20% by switching to pouches. This efficiency can lead to overall lower operational expenses, even if initial setup costs are higher.

In terms of logistics, flexible pouches are lighter and more compact. According to industry standards, this results in lower shipping costs. However, businesses must reflect on potential trade-offs. For example, while flexible pouches can be cost-saving, their environmental impact may be a concern for some consumers. To remain competitive, brands must weigh cost-saving benefits against sustainability goals.

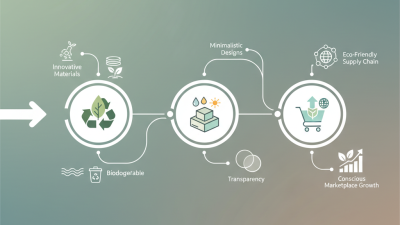

Considering Sustainability Practices in Flexible Packaging

Sustainability practices are vital in flexible packaging. According to industry reports, around 67% of consumers prefer eco-friendly packaging. This presents a significant opportunity for brands. However, not all flexible pouches are created equal. Many are still made from non-biodegradable materials. This can lead to waste issues and environmental concerns.

Choosing sustainable options is essential. Look for pouches made from recyclable or compostable materials. For instance, materials like bio-based polyethylene can reduce the carbon footprint. Additionally, consider lightweight designs. They require less material and reduce transportation emissions. That said, some brands still struggle to fully shift to these materials.

Innovations are emerging in the packaging industry. For example, a recent study found that flexible packaging can cut energy usage by 30% compared to rigid alternatives. Despite these advancements, challenges remain. Many companies face higher costs when switching to sustainable options. The future demands a balance between cost, functionality, and environmental impact.

Selecting the Right Supplier for Your Flexible Pouch Requirements

Choosing the right supplier for flexible pouch packaging is crucial. The global flexible packaging market is projected to grow significantly, reaching $300 billion by 2025. This growth highlights the need for quality suppliers who can deliver high-performance materials.

When assessing potential suppliers, consider their sustainability practices. A 2021 report revealed that 55% of consumers favor brands with eco-friendly packaging. Therefore, partnering with a supplier that prioritizes sustainable materials could enhance your market appeal. Look for certifications and proven initiatives that demonstrate environmental responsibility.

It's also vital to evaluate their production capabilities. Can they handle your specific requirements? Their ability to scale production is essential as demand fluctuates. A supplier's history with other clients can be insightful. However, some firms still struggle with quality control. Requests for samples are often overlooked. Always test prototypes thoroughly before committing to a large order. This can save headaches later on, ensuring the packaging meets both your standards and those of your consumers.

Related Posts

-

Top 10 Best Bags and Packaging Solutions for Sustainable Living

-

What is Commercial Packaging and Why It Matters for Your Business

-

How to Choose Eco Friendly Bags for Packaging Your Products Effectively

-

Top 10 Ways to Improve Packaging Efficiency and Sustainability for Your Business

-

Top Products and Packaging Trends to Watch in 2023 for Sustainable Choices

-

2025 Guide: How to Choose Bulk Packaging for Your Business Needs