Top 10 Ways to Improve Packaging Efficiency and Sustainability for Your Business

In today’s competitive marketplace, enhancing packaging efficiency and sustainability is more critical than ever. According to a recent report by Smithers Pira, the global sustainable packaging market is projected to reach $280 billion by 2027, driven by increased consumer demand for environmentally friendly solutions and the pressure on businesses to reduce their carbon footprint. To thrive in this evolving landscape, companies must prioritize strategies that not only improve packaging but also align with sustainability goals.

Industry expert Dr. Emily Johnson, a leading authority on packaging innovations, emphasizes the importance of this transition, stating, “To improve packaging is to not only elevate operational efficiency but also to embrace a responsibility towards our planet.” Her insights reflect a growing consensus among sustainability advocates that effective packaging practices can lead to significant cost savings while minimizing environmental impact. As businesses look to adapt to changing regulations and consumer preferences, the imperative to improve packaging becomes clear – it represents an opportunity for innovation that can benefit both the bottom line and the environment.

By exploring innovative strategies to improve packaging efficiency, businesses can not only enhance their operational effectiveness but also contribute to a more sustainable future. As we delve into the top ten ways to achieve these goals, it is vital to recognize the broader implications of our packaging choices on society and the planet.

Identifying Key Packaging Materials for Sustainability and Efficiency

The pursuit of sustainability and efficiency in packaging requires a keen understanding of materials that balance environmental impact with functional performance. Recent industry reports indicate that packaging accounts for nearly one-third of the waste generated in landfills, highlighting the urgent need for more sustainable choices. By identifying and utilizing key packaging materials, businesses can significantly reduce their ecological footprint. For instance, materials such as recycled paper, biodegradable plastics, and compostable films are gaining traction for their lower environmental impact compared to traditional packaging options.

Tips: Consider conducting a life-cycle analysis (LCA) of your packaging materials. This assessment will help you evaluate the environmental effects associated with different materials from production to disposal. By understanding this data, businesses can make informed decisions about which materials to adopt.

Moreover, embracing innovative alternatives like mushroom-based packaging or seaweed extracts can further enhance sustainability while meeting consumer demand for eco-friendly choices. According to a report by the Ellen MacArthur Foundation, transitioning to circular packaging solutions not only minimizes waste but can also reduce costs by up to 30% in some cases.

Tips: Engage with suppliers who prioritize sustainable practices and materials. Collaborating with companies focused on sustainability can provide access to cutting-edge solutions and contribute to a more circular economy. By making conscious choices about packaging materials, businesses can achieve efficiency while demonstrating their commitment to environmental responsibility.

Top 10 Key Packaging Materials for Sustainability and Efficiency

Analyzing the Role of Technology in Streamlining Packaging Processes

In today’s fast-paced business environment, leveraging technology to enhance packaging efficiency is crucial for maintaining a competitive edge. Modern advancements such as automation, artificial intelligence, and smart packaging solutions allow businesses to streamline their packaging processes significantly. For instance, automated packing machines can reduce labor costs and increase throughput, enabling companies to meet growing consumer demands without sacrificing quality.

Tip: Consider integrating IoT devices into your packaging process. These devices can monitor equipment performance in real-time, identifying potential issues before they escalate. By utilizing data analytics, businesses can also optimize packaging design and materials based on customer preferences and sustainability targets.

Furthermore, software solutions that facilitate inventory management and supply chain coordination can enhance the overall efficiency of packaging operations. By using cloud-based platforms, companies can gain better visibility into their logistics, ensuring timely delivery and minimizing waste. Developing a packaging strategy that embraces these technological innovations not only improves operational efficiency but also significantly contributes to sustainability efforts.

Tip: Implement a digital tracking system to monitor your packaging supply. This helps reduce excess inventory and waste, aligning with sustainability goals while ensuring your operations remain agile. By staying ahead of the curve with technology, businesses can transform their packaging processes into more efficient and ecologically responsible operations.

Top 10 Ways to Improve Packaging Efficiency and Sustainability for Your Business

| Method | Description | Benefits | Technology Used |

|---|---|---|---|

| Use Eco-Friendly Materials | Adopting biodegradable or recyclable packaging materials. | Reduces environmental impact and appeals to eco-conscious consumers. | Sustainable sourcing software |

| Optimize Design | Creating packaging that minimizes waste and maximizes product protection. | Improves shipping efficiency and reduces costs. | 3D modeling and simulation software |

| Implement Automation | Using automated systems for packing and labeling products. | Increases speed and efficiency while reducing labor costs. | Robotics and conveyor systems |

| Adopt Smart Packaging | Packaging integrated with technology that provides product information. | Enhances customer experience and improves supply chain transparency. | RFID and QR codes |

| Streamline Supply Chain | Improving coordination among suppliers, manufacturers, and distributors. | Reduces delays and lowers overall costs. | Supply chain management software |

| Conduct Regular Audits | Assessing packaging processes for inefficiencies and waste. | Identifies areas for improvement and cost savings. | Data analytics tools |

| Enhance Training Programs | Training staff on best practices for packaging and sustainability. | Improves efficiency and commitment to sustainable practices. | Learning management systems |

| Collaborate with Suppliers | Working closely with suppliers to develop sustainable packaging solutions. | Strengthens partnerships and enhances sustainability goals. | Partnership management tools |

| Monitor and Optimize Performance | Using KPIs to track packaging efficiency and sustainability metrics. | Ensures continuous improvement and accountability. | Performance management software |

Implementing Eco-Friendly Packaging Design Principles for Business Success

Implementing eco-friendly packaging design principles is not just a trend; it's a necessity for businesses looking to enhance their sustainability initiatives and operational efficiency. Studies indicate that consumers are increasingly favoring brands that prioritize environmentally conscious practices. According to a report by McKinsey & Company, nearly 60% of consumers are willing to change their shopping habits to reduce environmental impact. This shift highlights the importance of integrating sustainable packaging solutions in order to meet consumer expectations and enhance brand loyalty.

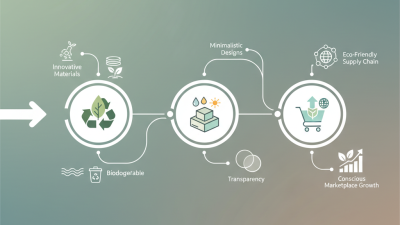

To begin with, businesses can adopt materials that are biodegradable or made from recycled content. This not only minimizes waste but also reduces the carbon footprint associated with manufacturing new materials. Moreover, investing in innovative designs that require less material without compromising quality can significantly enhance efficiency. For instance, utilizing minimalist packaging can lead to a reduction in production costs and shipping expenses, optimizing overall logistics.

Tips for improving packaging efficiency include evaluating the entire supply chain to identify areas for waste reduction, and considering package size and shape that align with transport and storage requirements. Another effective strategy is to employ smart labeling technologies that can better track inventory and reduce errors in order fulfillment, minimizing excess packaging. By making these thoughtful changes, businesses not only improve operational efficiency but also contribute positively to environmental sustainability.

Exploring Waste Reduction Strategies in Packaging Operations

In today's competitive market, organizations are increasingly recognizing the importance of waste reduction in their packaging operations to enhance both efficiency and sustainability. According to a report by the Environmental Protection Agency, packaging accounts for about 30% of the total municipal solid waste generated in the United States, amounting to more than 80 million tons annually. This statistical insight emphasizes the urgent need for companies to implement effective strategies aimed at minimizing waste throughout their packaging processes.

One effective method for reducing waste is through the adoption of eco-friendly materials. A survey conducted by the Green Packaging Group revealed that 73% of consumers are willing to pay a premium for sustainable packaging options. By utilizing biodegradable, recyclable, or reusable materials, businesses can significantly decrease their environmental impact and attract a customer base that values sustainability. Additionally, optimizing packaging design to minimize material usage without compromising product protection can lead to substantial reductions in waste.

Research from the World Packaging Organization indicates that a 10% reduction in packaging material can result in an overall cost saving of up to 25%, highlighting the financial and ecological benefits of streamlining packaging operations.

Moreover, implementing technology-driven solutions, such as automated packaging systems and data analytics, can lead to better inventory management and reduced excess packaging. Studies show that companies that leverage such technologies experience a 15-30% decrease in packaging waste. By fostering a culture of continuous improvement and sustainability, businesses allow for significant advancements in reducing packaging waste while maintaining operational efficiency and customer satisfaction.

Engaging Stakeholders in Sustainable Packaging Initiatives and Practices

Engaging stakeholders in sustainable packaging initiatives is crucial for businesses aiming to enhance both efficiency and sustainability. According to a report by the Ellen MacArthur Foundation, transitioning to sustainable packaging can reduce costs associated with material waste by up to 30%. This statistic underscores the importance of involving stakeholders, from suppliers to consumers, in collaborative efforts to innovate packaging processes. Engaging these parties helps identify shared goals and values, which can lead to more effective and sustainable solutions that benefit the entire supply chain.

Furthermore, a survey conducted by McKinsey & Company found that 67% of consumers prefer brands that use environmentally friendly packaging. This presents a significant opportunity for businesses to align their packaging strategies with consumer preferences, ultimately driving loyalty and brand advocacy. By involving stakeholders in discussions about sustainable materials and ethical sourcing practices, companies can not only improve their packaging but also foster a culture of sustainability within their operations. Engaging stakeholders effectively can lead to improved transparency and accountability, which are increasingly important in today's environmentally conscious market.

Related Posts

-

How to Choose the Right Products and Packaging for Your Business Needs

-

What is Commercial Packaging and Why It Matters for Your Business

-

2025 Guide: How to Choose Bulk Packaging for Your Business Needs

-

Top Products and Packaging Trends to Watch in 2023 for Sustainable Choices

-

How to Choose Eco Friendly Bags for Packaging Your Products Effectively